Digital twins in Industry 4.0

How KIT is powering the future of smart manufacturing

Industry 4.0 and digital twins

In the era of Industry 4.0, digital twins are no longer a futuristic concept. They’re a practical, powerful tool reshaping how manufacturers design, monitor, and optimise operations. At KIT, we’re proud to help businesses bridge the physical and digital worlds with precision, control, and clarity.

What is a digital twin?

A digital twin is a virtual replica of a physical asset, system, or process or entire manufacturing site. It uses real-time data and simulation models to mirror the behaviour and performance of its physical counterpart.

In manufacturing, this means you can visualise, analyse, and optimise everything from individual tools to entire production lines, without ever touching the shop floor.

Why digital twins matter in Industry 4.0?

Industry 4.0 is all about connectivity, automation, and data-driven decision-making. Digital twins are central to this vision because they enable:

- Predictive maintenance - Spot issues before they cause downtime.

- Process optimisation - Simulate changes and improvements virtually.

- Enhanced quality control - Monitor tool wear, calibration status, and usage patterns.

- Faster onboarding and training - Use digital models to train staff without interrupting operations.

How KIT supports digital twin technology?

At KIT, we provide the foundation for digital twins by digitising and organising your physical assets, starting with your tools and equipment. Here's how:

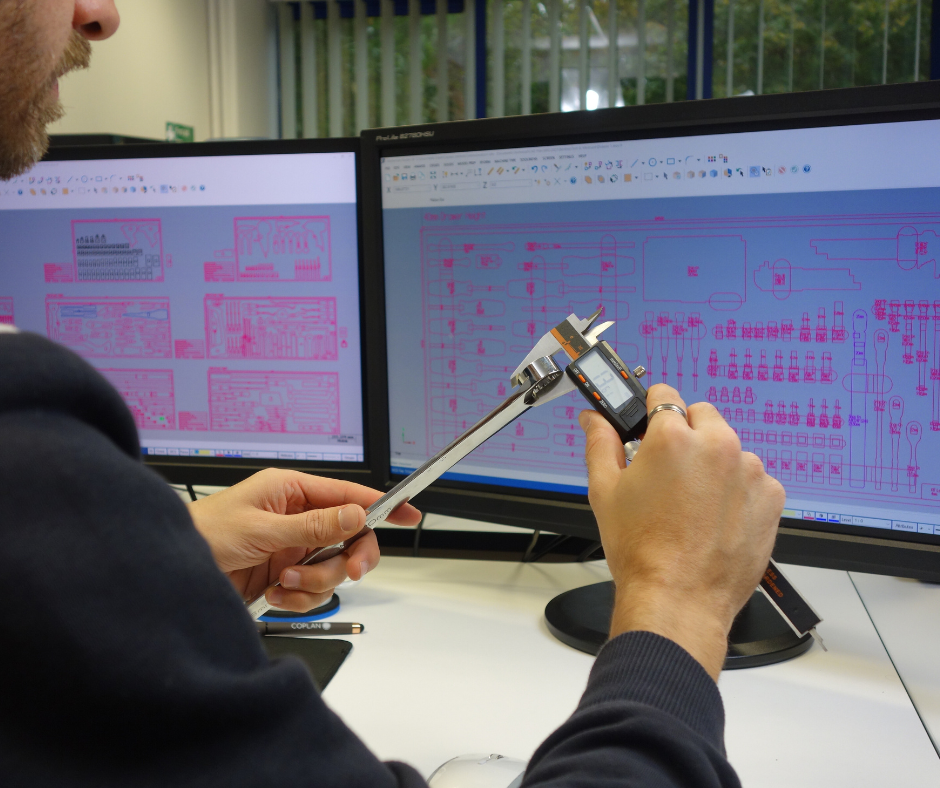

1. 2D Profiling & visual audits

We create accurate 2D profiles of your tools and equipment, forming the visual basis of your digital twin. These profiles are used to design custom foam inserts that transform tool drawers from chaos to order.

When these layouts are digitised in KIT, your entire tool inventory becomes catalogued, searchable, and visually represented. Tool audits become quick and simple, saving time and improving readiness for every shift.

2. Real-time inventory & calibration data

KIT tracks tool location, availability, condition, and calibration history. This live data feeds into your digital twin, ensuring it reflects the current state of your environment.

Planning a factory floor remodel, production ramp-up, or new project? Your digital twin lets you model and measure effectiveness before making changes.

KIT also automates calibration management and shares real-time status, removing uncertainty about tool readiness and improving safety and compliance.

3. Custom foam inserts & visual control

Custom foam inserts provide the first step toward organisation. When mirrored in KIT’s digital environment, they give teams ownership and accountability.

If tools go missing or break, reporting is instant, there’s no more end-of-shift surprises. Team members can log the issues immediately and this is flagged up in KIT’s dashboard. Managers can act quickly to order replacements, prioritise repairs, or reallocate resources to keep production moving.

4. Driving 5S and integration

KIT supports 5S principles: Sort, Set in Order, Shine, Standardise & Sustain. KIT drives workplace organisation by reducing clutter, freeing space, promoting pride and ownership and standardising tool management.

Integration with ERP systems and reporting tools like Power BI makes KIT a key enabler of smart factory analytics. KIT drives 5S practice forward, removing uncertainty and empowering teams to take control of their environments with pride.

The future: from digital twins to autonomous operations

We’re exploring IoT sensors, machine learning, self-serve onboarding and predictive analytics to make digital twins even smarter. Our goal? For KIT to help manufacturers not just see their operations but understand and improve them in real time.

Ready to build your digital twin?

Whether you're just starting your Industry 4.0 journey or looking to enhance your existing systems, KIT is here to help.

See KIT in action for yourself and make it your digital twin for tool control

Book a demo today and bring your tools, teams, and technology into perfect alignment.