5 common calibration mistakes and how to unlock peak performance

Effective tool calibration is as much about confidence and piece of mind as compliance

Why worry about tool calibration?

In manufacturing, tool calibration isn’t just a compliance checkbox to be ticked just before your audits are due, it’s a major factor in preventing unplanned downtime, optimising productivity and ensuring product quality.

With downtime costing many thousands of pounds per hour, no organisation can afford such interruptions, especially when they’re preventable. Even experienced teams can benefit from fine-tuning their calibration approach to save time, reduce costs, and strengthen reputation.

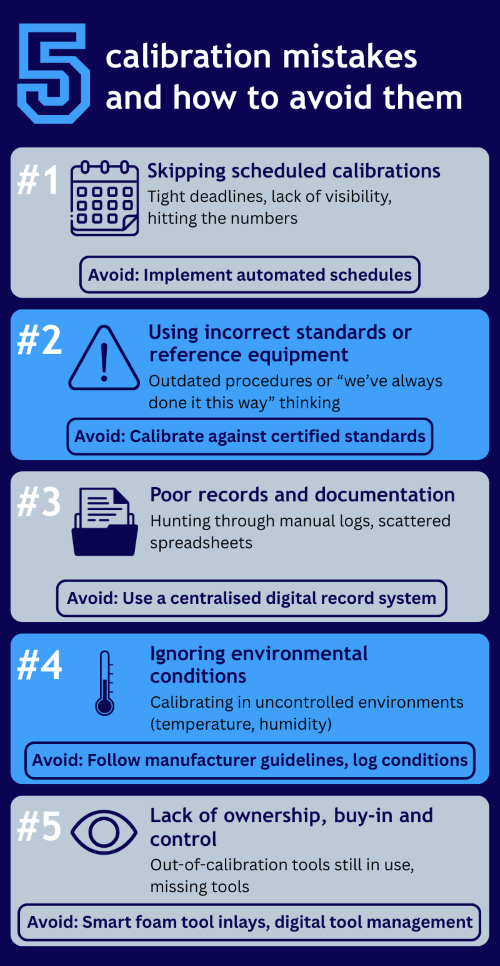

This blog covers the five most common calibration mistakes in manufacturing, their impact and how to avoid them. For a deeper dive of some of the other common calibration mistakes, read this article published in AutomationForum.co.

Mistake 1: Skipping scheduled calibrations

Whether it’s the pressure of tight deadlines, a drive to hit the numbers, cost-saving attempts or just down to a lack of visibility, skipping calibrations always costs more in the long-run.

Whether it results in increased measurement errors, equipment malfunction or breakdown, product rework or quality issues, safety incidents or failed audits, they all hurt the organisation. Whereas staying on schedule ensures accuracy, reliability, and long-term savings.

Avoiding it can be simple. Implement automated schedules, which send out early and overdue reminders and increase their visibility via dashboards that are shared across the management team, so that nothing is left to chance.

Mistake 2: Using incorrect standards or reference equipment

Whilst staff turnover and training can certainly be a factor in not adhering to correct calibration standards, it’s more often due to lack of a clearly documented procedure and nominated test equipment and referring to outdated standards.

By not keeping up with the latest standards or equipment, tools can often seem like they are giving the right results, only to later find that the results were inaccurate and tools were out of tolerance. In severe circumstances, this can lead non-compliances, fines, product defects and other reputational damage.

Updating processes ensures your team benefits from the latest standards and best practices and with a clear calibration policy outlining measurements, expected results and nominated test equipment, there can be no confusion.

Mistake 3: Poor records and documentation

Relying on manual logs and practices that can be traced back decades is still commonplace. Logs filed away somewhere in old lever arch files, held on clipboards scattered around the shop floor or even on various spreadsheets stored on different servers do not create the right impression on an auditor who wants to see records that are complete, legible and controlled.

This can cost the organisation dearly, with audit failures and inability to prove compliance leading to sanctions, fines or a complete cessation of production until practices are changed and shown to be under control.

Avoiding this needn’t be scary. Digital records not only make calibrations easier to manage, they also make audits smoother and showcase your commitment to quality.

Mistake 4: Ignoring environmental conditions

When calibrating tools, environment conditions such as temperature, humidity and air quality can impact the consistency and accuracy of your calibration test results just as much as dirt, wear or damage on the tool or the test equipment.

Avoiding this is usually means observing the manufacturer’s guidelines and logging the test conditions under which the calibrations took place. On highly specialist or sensitive equipment, controlled conditions protect your tools and ensure consistent, accurate results. Engaging external calibration services who live and breathe these ultra-controlled conditions is often the most cost-efficient way to guarantee the validity of the calibration..

Always ensure that regardless of whether conducted internally or externally, environmental conditions are captured as part of the calibration record in case you need to rule out such factors in any root cause analysis for any failures.

Mistake 5: Lack of ownership, buy-in and control

Ownership of key tasks like tool calibration is sometimes de-prioritised when in a pinch. But as stated earlier, it is a mistake that is likely to lead to errors in production or safety hazards that slow down or even halt production. Instead, empowering teams, as detailed in our earlier blog on “7 ways to ease the pain of calibration”, with clear ownership builds confidence and pride in quality and all but eliminates these avoidable issues.

Equally, visual tool control solutions like foam inlays in tool cabinets and shadowboards twinned with digital tool management solutions ensure that tools don’t get mixed up or lost between shifts or lines and out-of-calibration tools are taken out of use thus avoiding costly usage errors. This investment gives teams confidence that they can trust their tools, and invokes an added sense of pride, care and ownership in wanting to look after their tools properly.

Conclusion

Avoiding these mistakes and adopting best practices isn’t just about compliance, it’s about confidence in every measurement. And it can be a lot easier than it seems.

Recently awarded Calibration Product of the Year, KIT makes calibration management simple, visual, and audit-ready.

Here’s how KIT helps avoid these pitfalls:

- Automated scheduling with reminders and dashboards for visibility.

- User-defined digital calibration policies aligned with ISO and manufacturer standards.

- Centralised records for calibration and audit histories.

- Environmental data logging and certificate storage.

- Visual control systems and a digital twin that promote ownership, accountability and pride.

Tired of making these mistakes and want confidence in your tools?

Book a demo today and see how KIT can transform your calibration processes into best practice