10 tips for developing effective calibration practices

Tool calibration is critical to precision and control in engineering and manufacture, yet it is so often overlooked or avoided.

Calibrating tools sounds straightforward; just follow a process, take some measurements and adjust where necessary to stay within tolerance and record the results.

But people often sidestep it for a mix of practical and psychological reasons. Here’s why:

- Time constraints: Calibration can be time-consuming without good systems, especially in busy work environments where speed is prized over precision.

- Overconfidence in accuracy: If a tool seems to be working "well enough," people assume it's still accurate, even if it's drifted over time.

- Lack of awareness or training: Not everyone knows how or why calibration matters, especially for newer or non-technical users.

- Inconvenience: Some tools need special equipment or need to be sent off-site to be calibrated, which disrupts workflows.

- Cost factors: Calibration services or buying the right reference standards can be expensive, especially for smaller operations.

- Perceived low risk: In contexts where extreme precision isn’t necessary, people might skip calibration, figuring the consequences are minor.

Here’s why it matters:

- Reliable results: Regular calibration ensures tools perform as expected and avoid costly mistakes or safety risks.

- Regulatory compliance: Industries like healthcare, aerospace, and manufacturing often require calibration to meet legal standards.

- Trust & reputation: A mis-calibrated tool can undermine results and damage professional credibility.

People often prioritise speed over certainty, until something goes wrong.

So how do you counter this and tighten up your calibration practices?

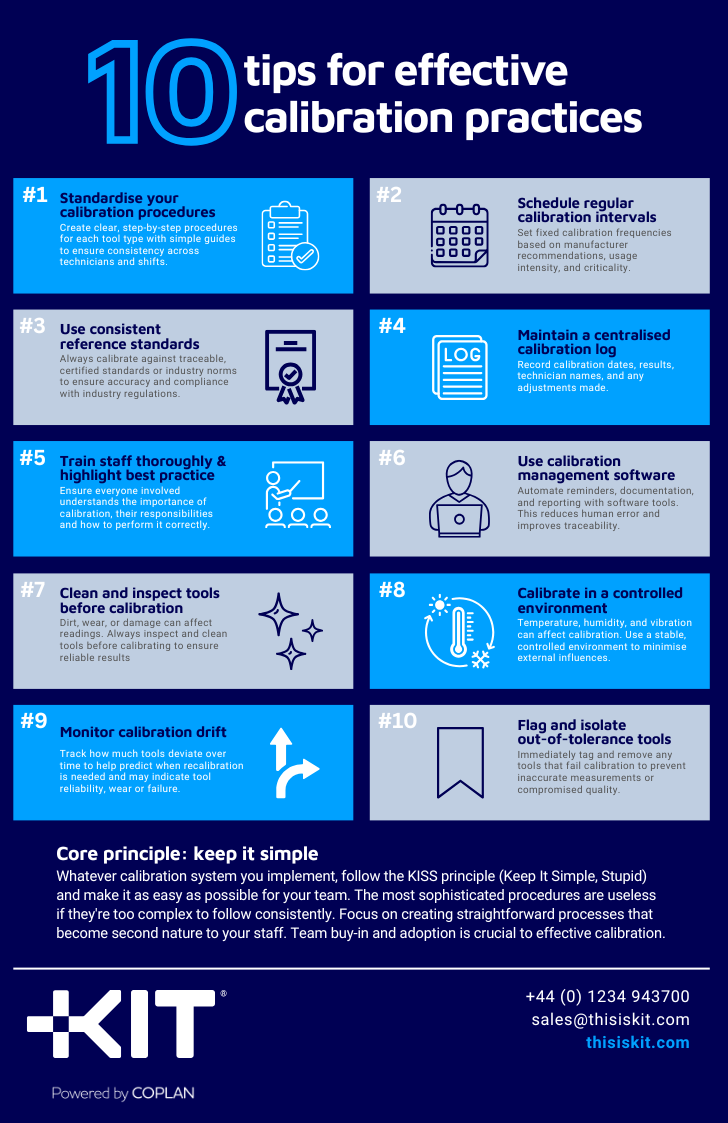

The 10 tips for effective calibration

Here’s 10 practical tips for making effective calibration a reality:

1. Standardise your calibration procedures

Create clear, step-by-step procedures for each tool type. Use checklists or simple guides to ensure consistency across technicians and shifts.

2. Schedule regular calibration intervals

Set fixed calibration frequencies based on manufacturer recommendations, usage intensity, and criticality. Use calendar reminders or software to automate scheduling.

3. Use consistent reference standards

Always calibrate against traceable, certified standards or industry norms to ensure accuracy and compliance with industry regulations. Being consistent with your approach to calibration of tools over time simplifies compliance and makes it less painful for the technicians doing the calibrations.

4. Maintain a centralised calibration log

Record calibration dates, results, technician names, and any adjustments made. Digital calibration management systems are ideal for easy access and audits and give that confidence that checks are being done and issues captured.

5. Train staff thoroughly and highlight best practice

Ensure everyone involved understands the importance of calibration, their responsibilities and how to perform it correctly. Include calibration in onboarding and refresher training and celebrate good practice within the team.

6. Use calibration management software

Automate reminders, documentation, and reporting with software tools. This reduces human error and improves traceability.

7. Clean and inspect tools before calibration

Dirt, wear, or damage can affect readings. Always inspect and clean tools before calibrating to ensure reliable results.

8. Calibrate in a controlled environment

Temperature, humidity, and vibration can affect calibration. Use a stable, controlled environment to minimise external influences.

9. Monitor calibration drift

Track how much tools deviate over time. This helps predict when recalibration is needed and may indicate tool reliability, wear or failure. Centralising the calibration history of your tools gives you that at a glance knowledge of potential problems.

10. Flag and isolate out-of-tolerance tools

Immediately tag and remove any tools that fail calibration to prevent inaccurate measurements or compromised quality. Respond early to flagged and recurring issues to reinforce importance. Engage team in refining procedures and tool design or selection / testing of alternatives.

Calibrating tools and instruments doesn’t have to be a tedious chore. By blending smart automation, streamlined workflows, and clear accountability, you can turn calibration from a dreaded task into a seamless part of your routine. But whatever you do, use the KISS principle and make it as easy as possible as team buy-in and adoption is so crucial to effective calibration.

Book a demo

If you'd like to know more about how our KIT solution could help you develop effective tool calibration practices in your organisation and see it in practice, then book a demo with us and see how we can take the pain away.